| Availability: | |

|---|---|

| Quantity: | |

| Item | Passivat Stainless Steel Metal part for Electronic Appliances Communications |

| Size | Customized, according to drawing |

| Technological Design | Process analysis and review of product drawings; Draw up a processing plan; Compile process specification and design and manufacture of process equipment |

| Material | Rolled steel, Stainless steel, Steel, Aluminum, Aluminum alloy, Corrosion resistant aluminum… Or Customized |

| Tolerance | +/-0.002mm, 100% QC quality inspection before delivery, can provide quality inspection form testing equipment |

| Processing | CNC punching, Laser cutting, CNC bending, Welding |

| Heat Treatment | Normalizing, Annealing, Tempered, Aging, Tempering, Quenching |

| Special Processing | EDM, Wire EDM, Electrochemical machining, Laser processing |

| Equipment Support | Welding Machine(Panasonic), Laser Marking Machine(Hans laser), Bending Machine (Amada), CNC Laser Pipe Cutting Machine(Bystronic), CNC Punching Machine(Amada), Automatic Laser Pipe Cutting Machine(Songu), Desktop Laser Welding Machine(NINE ), Automatic Deburring and Wire Drawing Machine(XINDING) , etc. |

| Surface | Wire drawing, Sandblasting, Baking varnish, Dusting, Electroplate, Anodic oxidation, Silk screen, Plastic impregnation, Imprint, etc. |

| Certification | ISO 9001:2015, ISO 13485:2016, ISO 14001:2015, AS 9100D, CWB |

| Testing Equipment | Welding Seam Inspection Scale(CWB), Digital Display Push-pull Meter(Eidelberg), Laser Digital Level(DAYOU), Helium Mass Spectrometry Leak Detector(Leybold), etc. |

| Supply Ability | 100,000 CNC machining parts, 3,000 Sheet metal parts, 50 Module per Day |

| Quotation Against | 2D drawings (PDF, JPG, DWG), 3D drawings (STP, IGS) or sample |

| Payment Term | T/T, L/C, D/P, D/A |

| Lead Time | 15-20days |

ABOUT US

—21+ years of experience in Precision Machining / Sheet Metal Processing / Precision Module / OEM Modules manufacturing

—200,000+m² facility , 3000+ employees with more than 30% R&D engineer

—700+ advanced CNC machine & Sheet Metal Processing Machine from Germany and Japan, such as 5 axis DMG & MAZAK CNC Machine, Bystronic Laser Cutting Machine, Amada Punching & Bending Machine , which accuracy can be up to 0.002mm

—100+ high accuracy 3D / 2D INSTRUMENT from Germany, Italy, Japan and Switzerland, such as CMM (ZEISS-Germany), MRS(GNR-Italy ), Projector (MITUTOYO-Japan) , Altimeter (TESA-Switzerland), etc

— ISO9001, ISO14001, ISO13485, AS9100D, CWB certification

21+ YEARS EXPERIENCE

200,000+㎡ FACILITY

3000+ EMPLOYEES

700+ ADVANCED CNC MACHINE

100+ HIGH ACCURACY 3D/2D INSTRUMENT

8+ MANUFACTURING PLANTS

30+ OFFICES

SYSTEM CERTIFICATION

PRECISION MACHINING PRODUCT

Machining Parts/Turning Parts/Milling Parts/Truning Milliing Compound Parts/Sheet Metal Parts/Module

PRECISION MACHINING CAPABILITY

Guangdong World Precision has introduced a large number of high-end precison five-axis, horizontal, turning-milling composite and advanced testing equipment from Germany and Japan; a leading role in the global precison processing industry in term of the product precision machining and processing capabilities.

STANDARDIZED QUALITY INSPECTION

OUR TEAM

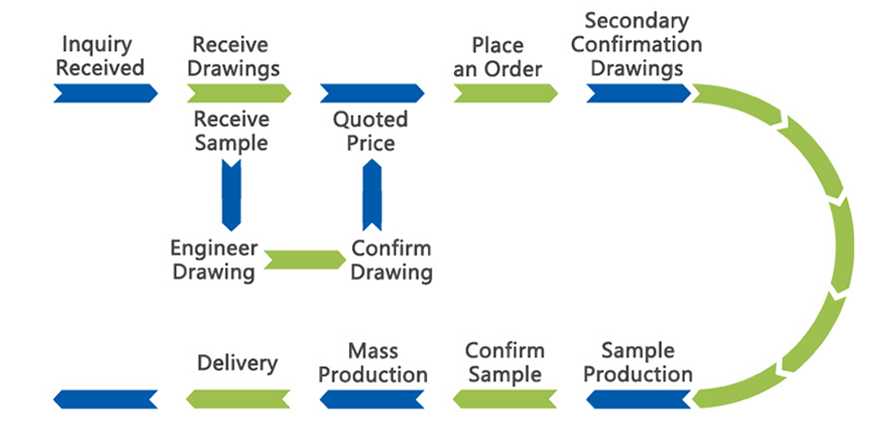

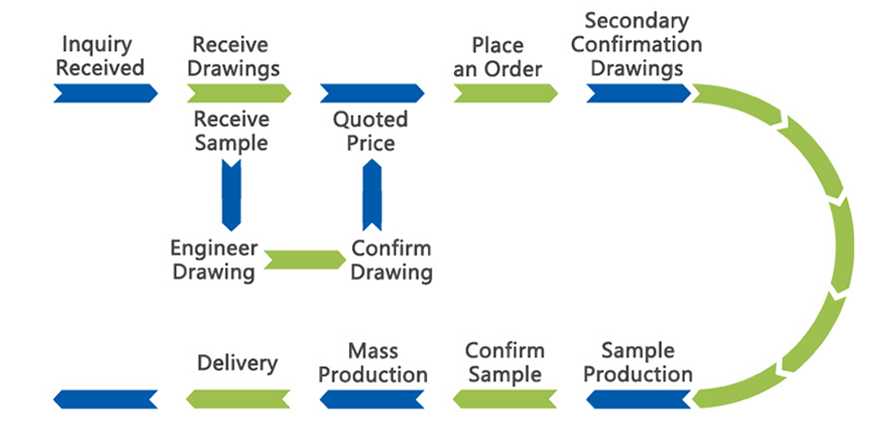

FLOW CHART

FAQ

Q1: Are you a trading company or a factory?

A1: We are a factory.

Q2: How long is your delivery time?

A2: Samples are generally 3-7 days; bulk orders are 10-25 days, depending on the quantity and parts requirements.

Q3: Do you provide samples? Is it free or extra?

A3: Yes, we can provide samples, and we will charge you based on sample processing. The sample fee can be refunded after placing an order in batches.

Q4: Do you provide design drawings service?

A4: World Precison strives to provide the transparency to its customers during the entie process of the production. RTTS system under development will provide real time tracing access to the customers regarding their parts in production.

World Precison is conduting its customer-oriented demand identification and change management process throughout the whole course to make sure its customers being correctly understood and to provide its customers with the possibility of change in design or process at any time in case needed during the entire course.

Q5: What about drawing confidentiality?

A5: Sign NDA agreement with the customer. Completely remove customer information from the produciton site and drawing, and ensure that it will not be leaked to anyone else.

Q6: How do you guarantee the quality of your products?

A6: We are equipped with a variety of advanced testing equipment, forming a comprehensive quality management system focusing on IQC, IPQC, FQC, OQC, AQE, SQE, calibration, CQE, etc. Our company has passed ISO9001, ISO13485, ISO 14001, AS9100D and other quality certifications.

| Item | Passivat Stainless Steel Metal part for Electronic Appliances Communications |

| Size | Customized, according to drawing |

| Technological Design | Process analysis and review of product drawings; Draw up a processing plan; Compile process specification and design and manufacture of process equipment |

| Material | Rolled steel, Stainless steel, Steel, Aluminum, Aluminum alloy, Corrosion resistant aluminum… Or Customized |

| Tolerance | +/-0.002mm, 100% QC quality inspection before delivery, can provide quality inspection form testing equipment |

| Processing | CNC punching, Laser cutting, CNC bending, Welding |

| Heat Treatment | Normalizing, Annealing, Tempered, Aging, Tempering, Quenching |

| Special Processing | EDM, Wire EDM, Electrochemical machining, Laser processing |

| Equipment Support | Welding Machine(Panasonic), Laser Marking Machine(Hans laser), Bending Machine (Amada), CNC Laser Pipe Cutting Machine(Bystronic), CNC Punching Machine(Amada), Automatic Laser Pipe Cutting Machine(Songu), Desktop Laser Welding Machine(NINE ), Automatic Deburring and Wire Drawing Machine(XINDING) , etc. |

| Surface | Wire drawing, Sandblasting, Baking varnish, Dusting, Electroplate, Anodic oxidation, Silk screen, Plastic impregnation, Imprint, etc. |

| Certification | ISO 9001:2015, ISO 13485:2016, ISO 14001:2015, AS 9100D, CWB |

| Testing Equipment | Welding Seam Inspection Scale(CWB), Digital Display Push-pull Meter(Eidelberg), Laser Digital Level(DAYOU), Helium Mass Spectrometry Leak Detector(Leybold), etc. |

| Supply Ability | 100,000 CNC machining parts, 3,000 Sheet metal parts, 50 Module per Day |

| Quotation Against | 2D drawings (PDF, JPG, DWG), 3D drawings (STP, IGS) or sample |

| Payment Term | T/T, L/C, D/P, D/A |

| Lead Time | 15-20days |

ABOUT US

—21+ years of experience in Precision Machining / Sheet Metal Processing / Precision Module / OEM Modules manufacturing

—200,000+m² facility , 3000+ employees with more than 30% R&D engineer

—700+ advanced CNC machine & Sheet Metal Processing Machine from Germany and Japan, such as 5 axis DMG & MAZAK CNC Machine, Bystronic Laser Cutting Machine, Amada Punching & Bending Machine , which accuracy can be up to 0.002mm

—100+ high accuracy 3D / 2D INSTRUMENT from Germany, Italy, Japan and Switzerland, such as CMM (ZEISS-Germany), MRS(GNR-Italy ), Projector (MITUTOYO-Japan) , Altimeter (TESA-Switzerland), etc

— ISO9001, ISO14001, ISO13485, AS9100D, CWB certification

21+ YEARS EXPERIENCE

200,000+㎡ FACILITY

3000+ EMPLOYEES

700+ ADVANCED CNC MACHINE

100+ HIGH ACCURACY 3D/2D INSTRUMENT

8+ MANUFACTURING PLANTS

30+ OFFICES

SYSTEM CERTIFICATION

PRECISION MACHINING PRODUCT

Machining Parts/Turning Parts/Milling Parts/Truning Milliing Compound Parts/Sheet Metal Parts/Module

PRECISION MACHINING CAPABILITY

Guangdong World Precision has introduced a large number of high-end precison five-axis, horizontal, turning-milling composite and advanced testing equipment from Germany and Japan; a leading role in the global precison processing industry in term of the product precision machining and processing capabilities.

STANDARDIZED QUALITY INSPECTION

OUR TEAM

FLOW CHART

FAQ

Q1: Are you a trading company or a factory?

A1: We are a factory.

Q2: How long is your delivery time?

A2: Samples are generally 3-7 days; bulk orders are 10-25 days, depending on the quantity and parts requirements.

Q3: Do you provide samples? Is it free or extra?

A3: Yes, we can provide samples, and we will charge you based on sample processing. The sample fee can be refunded after placing an order in batches.

Q4: Do you provide design drawings service?

A4: World Precison strives to provide the transparency to its customers during the entie process of the production. RTTS system under development will provide real time tracing access to the customers regarding their parts in production.

World Precison is conduting its customer-oriented demand identification and change management process throughout the whole course to make sure its customers being correctly understood and to provide its customers with the possibility of change in design or process at any time in case needed during the entire course.

Q5: What about drawing confidentiality?

A5: Sign NDA agreement with the customer. Completely remove customer information from the produciton site and drawing, and ensure that it will not be leaked to anyone else.

Q6: How do you guarantee the quality of your products?

A6: We are equipped with a variety of advanced testing equipment, forming a comprehensive quality management system focusing on IQC, IPQC, FQC, OQC, AQE, SQE, calibration, CQE, etc. Our company has passed ISO9001, ISO13485, ISO 14001, AS9100D and other quality certifications.